Since the 1960s, NASA has relied on an old yet dependable technology for powering the International Space Station (ISS), satellites, and other space vehicles: nickel-hydrogen (Ni-H2) batteries (NHBs). These batteries are revered for their durability, long lifespan, and outstanding safety record, even under the most extreme conditions. Let's explore how these batteries function and their potential benefits for modern applications.

Tests conducted on these batteries often involve harsh treatment, such as deliberate perforation using nails or firearms. The results consistently prove the remarkable resilience of NHBs, as there's no explosion, fire, or material ejection—even in cases of hypervelocity impact. The surface temperature remains at a manageable 44 degrees Celsius (112 degrees Fahrenheit) and the pressure and voltage rapidly dissipate, preventing any catastrophic rupture.

Unlike common lithium-ion batteries, NHBs do not develop dendrites, which are tiny metal structures that build upon anodes during charging and can cause short circuits or other failures. This means the batteries can go through approximately 30,000 cycles—or around 30 years of daily use—without compromising their integrity, making them a low-maintenance solution for long-term energy storage.

The battery's chemical makeup is mainly hydrogen and water, meaning they're also environmentally friendly. Additionally, their manufacturing process is straightforward and uses abundant elements, nickel, and hydrogen, thus easing supply chain and cost issues.

Old Tech is New Again

So why is this legacy battery design now relevant again? And why have NHBs and their potential applications been overlooked until now?

Well, despite a 250 percent surge in nickel prices in 2022, the low-maintenance nature and longevity of these batteries potentially save substantial operational costs, particularly for renewable energy storage facilities. Also, when the time comes for disposal, these batteries are almost 100 percent recyclable. But the real reason these legacy batteries have been dormant is cost. Sky high cost!

But that all might soon change. EnerVenue, a California-based company specializing in energy storage solutions, has embarked on a large grid-scale gigawatt storage facility that will be located in Kentucky and will seek to capitalize on all the potential upsides of using NHBs.

EnerVenue feels that, like the proven technology used by NASA for more than 30 years, their Energy Storage Vessels™ (ESVs) feature an exceptionally long lifespan, eliminating the need for augmentation or oversizing. ESVs can be easily mounted in racks, containers, or stacked in custom warehousing. Their unique chemistry eliminates the need for preventative fire suppression. They can also reliably operate in a wide ambient temperature range without supplementary HVAC. ESVs dramatically reduce operating expenses and feature a much lower cost-per-cycle compared to lithium-ion chemistries.

3/30/30,000: Energy Storage Vessels can cycle up to 3 times per day without rest and boast an expected lifetime of 30 years / 30,000 cycles – enabling unique applications and business models for developers, integrators, and owners. - EnerVenue

The company is addressing the astronomical cost problem primarily by utilizing economies of scale and mass production of their ESVs. These batteries are still pricey, but EnerVenue’s large "gigafactory"—and potential future ones like it—will make them more affordable by eliminating the need for custom designs. By the end of 2023, EnerVenue expects the gigafactory to begin production.

Featured Products

Irrespective of the specific battery design, converting potential energy into electrical energy necessitates the implementation of a resilient and high-efficiency Battery Management System (BMS). This week's New Tech Tuesday highlights the introduction of BMS solution devices by Vishay / Dale and Nexperia.

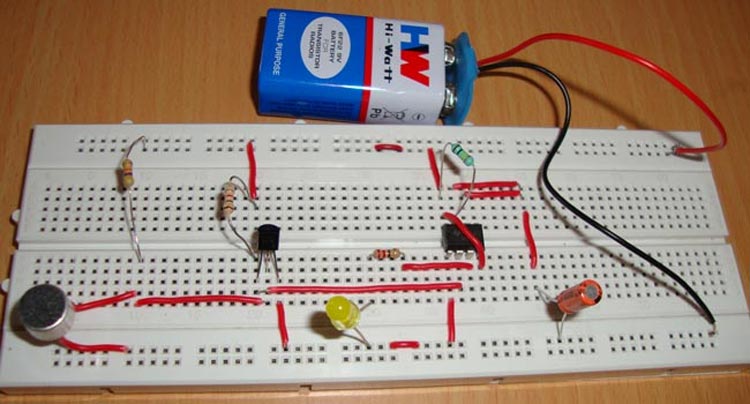

The HV Intelligent Battery Shunt HV-IBSS-USB from Vishay / Dale is a reference design made to easily evaluate the low Temperature Coefficient of Resistance (TCR) of shunt WSBE8518. It uses a single USB-C connector to provide power to the circuit and to emulate a serial interface so engineers can conveniently make voltage, current, and temperature readings.

Due to the low TCR of the WSBE8518 (maximum ± 10ppm/K for 100μΩ) alongside the choice of low thermal drift components in the analog frontend, this reference design can achieve an overall TCR of approximately 44ppm/K max. without thermal compensation over the whole temperature range. The device is factory calibrated (values stored in onboard EEprom) to allow for current measurements with 0.2 percent and thermal drift for currents in the range of ±500A.

The TCR is a crucial parameter in current sensing measurements, especially in applications like BMS that involve monitoring and managing current flow in various components, including battery shunts. TCR indicates how a material's electrical resistance changes with changes in temperature. It's expressed as a fractional change in resistance per degree Celsius change in temperature (ΔR/R0 per °C), usually in parts per million per degree Celsius (ppm/°C).

In BMS, TCR plays a significant role for several reasons, including the precise measurement of current flowing into and out of the battery, as well as throughout the battery system. This is essential for monitoring the state of charge (SoC) and state of health (SoH) of the battery. TCR helps compensate for changes in resistance due to temperature variations, allowing for more accurate and consistent current measurements. Additionally, accurate current measurements enable the BMS to detect anomalies and potentially hazardous conditions like overcurrent situations, which can lead to thermal runaway or other safety risks. By compensating for temperature effects, the BMS can respond appropriately to changes in current flow, enhancing the overall safety and efficiency of the battery system.

Nexperia eMode GaN FETs offer a voltage range of 100V to 650V and superior ultra-high frequency switching performance. These general-purpose enhancement mode (eMode) Gallium Nitride Field-Effect Transistors (GaN FETs) deliver fast transition and switching capability with minimal conduction and switching losses.

Enhancement mode FETs are "normally-off," meaning that by default, the transistor is in an "off" state until a specific voltage to its gate terminal is applied, activating the transistor and letting current flow. This type of GaN FET is commonly used in power electronics because it's safer and more predictable—if there's no voltage applied, it stays off, reducing the risk of accidental current flow.

These power FETS are available in a DFN 8mm x 8mm surface mount package. Applications include high power density and high-efficiency power conversion, AC-to-DC and DC-to-DC converters, fast battery charging, and motor drives. For 650V and ≤ 150V industrial and consumer applications, Nexperia e-Mode GaN FETs provide the balance between switching performance and robustness.

Tuesday’s Takeaway

Nickel-hydrogen batteries, despite being old technology, continue to prove their worth, especially in the renewable energy sector. Although their initial cost is high due to the use of expensive metals, advancements in mass production and the potential for cost-saving through their durability and longevity make them an attractive option as energy storage vessels for companies like EnerVenue. As we gear towards more sustainable energy solutions, it's crucial to revisit and optimize tried-and-true technologies like NHBs, which have been quietly powering our space missions for decades.

In the realm of battery management, Vishay / Dale and Nexperia present solutions like the HV Intelligent Battery Shunt, which leverages TCR technology for current sensing measurements to ensure accurate current monitoring while enhancing battery safety and efficiency. Nexperia’s eMode GaN FETs represent a safer and more predictable option in high-power density electronics, designed to remain off until activated, thereby reducing the risk of unintended current flow. These FETs offer efficient power conversion in various applications, showcasing a balance between switching performance and robustness.

Innovation continues to merge lessons from NASA's legacy technology with modern applications, providing solutions that bridge the gap between reliability, sustainability, and efficiency in energy storage and management.

Original Source: Mouser

About the Author

Rudy is a member of the Technical Content Marketing team at Mouser Electronics, bringing 35+ years of expertise in advanced electromechanical systems, robotics, pneumatics, vacuum systems, high voltage, semiconductor manufacturing, military hardware, and project management. As a technology subject matter expert, Rudy supports global marketing efforts through his extensive product knowledge and by creating and editing technical content for Mouser's website. Rudy has authored technical articles appearing in engineering websites and holds a BS in Technical Management and an MBA with a concentration in Project Management. Prior to Mouser, Rudy worked for National Semiconductor and Texas Instruments.

Rudy is a member of the Technical Content Marketing team at Mouser Electronics, bringing 35+ years of expertise in advanced electromechanical systems, robotics, pneumatics, vacuum systems, high voltage, semiconductor manufacturing, military hardware, and project management. As a technology subject matter expert, Rudy supports global marketing efforts through his extensive product knowledge and by creating and editing technical content for Mouser's website. Rudy has authored technical articles appearing in engineering websites and holds a BS in Technical Management and an MBA with a concentration in Project Management. Prior to Mouser, Rudy worked for National Semiconductor and Texas Instruments.