When starting a project, the first challenge is to select the best parts for it. In the case of a tracking project, the main parts would be the GPS and GSM modules are the main components. This article will help you find the best ones from the choices available in the market. We will discuss the features or specifications you should check before sourcing these parts.

Things to Consider before Purchasing a GPS Module

- Size: Sizing matters as it may affect not only the size constraints but also other technical parameters like lock time and accuracy etc. For applications like tracking, we will need the module with the smallest size possible without any compromise in the accuracy or the response time, etc.

- Update Rate: The update rate of a GPS or GNSS module is basically how often it recalculates and reports its position. The standard for most devices is 1Hz (Only once per second). 5-10Hz update rates can be considered if you need them to work on faster vehicles which are not required in most real-life scenarios.

- Communication Interface: It’s the interface used to communicate with the GPS Module. Serial/TTL or the USB interface is the most commonly used interface type by the GPS module.

- Communication Speed/Baud Rate Refers to the speed of communication between the microcontroller and the GPS module, in the case of serial interface it is called the baud rate. Higher the baud rate allows for faster GPS data to be sent to the MCU.

- Navigation Sensitivity dBm figure dictates how prone the GPS module is able to capture the signal from the satellites. Higher dBm indicates that the module is able to better pick up satellite signals

- Power Requirements include the working voltage and the power consumption. It is necessary to select the proper device because in most cases the modules will be battery powered and we will need to conserve the battery to maximize working time. The average power consumption of most common GPS modules is around 30mA at 3.3V

- Number of Channels that the GPS module runs will affect your time to first fix (TTFF). Since the module doesn’t know which satellites are in view, the more frequencies/channels it can check at once, the faster a fix will be found. After the module gets a lock or fix, some modules will shut down the extra blocks of channels to save power. If you don’t mind waiting a little longer for a lock, 12 or 14 channels will work just fine for tracking.

- Accuracy: Lower the distance it can get down to = Higher accuracy. Usually able to find out your location within 30 seconds, down to +/- 10m. Most modules can get it down to +/-3m

- Antenna: Remember, that little GPS module is receiving signals from satellites about 12,000 miles away in the sky. For the best performance, you want a clear path between the antenna and most of the sky. Weather, clouds, and snowstorms shouldn't affect the signal, but things like trees, buildings, mountains, and the roof over your head, will all create unwanted interference, and your GPS accuracy will suffer. So, the choice of the proper antenna is very crucial.

- Gain: The gain is the efficiency of the antenna in any given orientation. This applies to both transmitting antennas and receiving antennas.

- Chipset: The GPS chipset is responsible for doing everything from performing calculations, to providing the analog circuitry for the antenna, to power control, to the user interface. It’s a lot of work, and yet that’s exactly what these tiny GPS units are doing. The chipset is independent of the antenna type, therefore you can have a range of different antennas for GPS modules with specific chipsets. Common chipsets are ublox, SiRF, and SkyTraq, and all contain very powerful processors that allow for fast acquisition times and high reliability. The differences between chipsets usually fall on a balance between power consumption, acquisition times, and accessibility of hardware. So, choosing the best one for our application is a crucial part.

- Price: Last but not least the price of the module is very important. It is very important to keep everything under the budget.

- Time to First Fix(TTFF): Time taken for satellite lock after power-up or reboot.

So now as we know what we are looking for in a GPS Module, let us take a look at a few GPS Modules in the market now:

NEO-6M GPS Module

Considered as one of the more popular GPS modules in the market, the NEO-6M module is a family of stand-alone GPS receivers from the NEO-6 module series.

Based on the list of considerations:

Size: 23mm x 30mm

Update Rate: 1 Hz, 5Hz maximum

Power Requirements:

- Power Supply Voltage: 3V – 5V

Baud Rate: 9600

Communication Interface: UART

Sensitivity: -161dBm

Number of Channels: 50

Time to First Fix:

- Cold Start: 27s

- Warm Start: 27s

- Hot Start: 1s

- Aided Starts: <3s

Antennas: Includes external patch antenna

Accuracy:

- 2.5m GPS Horizontal Position Accuracy

Product Applications:

- Battery-operated mobile devices

- GPS tracker

- GPS navigator

NEO-M8N GPS Module

The NEO-M8M GPS Module with Ceramic Active Antenna series of concurrent GNSS modules is built on the high-performing M8 GNSS engine in the industry-proven NEO form factor. The NEO-M8M is optimized for cost-sensitive applications, while NEO-M8N/M8Q provides the best performance and easier RF integration. The NEO-M8N offers high performance also at low power consumption levels. The future-proof NEO-M8N includes an internal Flash that allows future firmware updates. This makes NEO-M8N perfectly suited to industrial and automotive applications.

Based on the list of considerations:

Size: 23mm x 30mm

Update Rate: 1 Hz, 5Hz maximum

Power Requirements:

- Power Supply Voltage: 3.6V

Baud Rate: 9600

Communication Interface: UART/USB/SPI

Sensitivity: -164dBm

Number of Channels: 72

Time to First Fix:

- Cold Start: 26s

- Hot Start: 1s

- Aided Starts: 4s

Antennas: Includes external patch antenna

Accuracy:

- 2.5m GPS Horizontal Position Accuracy

Product Applications:

- Battery-operated mobile devices

- GPS tracker

- GPS navigator

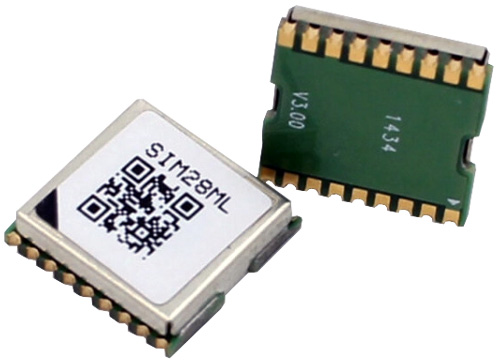

SIM28ML

SIM28ML is a small, high-performance, and reliable GPS module. This is a standalone L1 frequency GPS module in an SMT type and it is designed with an MTK high sensitivity navigation engine, which allows you to achieve the industry’s highest levels of sensitivity, accuracy, and Time-to-First-Fix (TTFF) with the lowest power consumption.

Size: 10.1*9.7*2.5mm

Update Rate: Up to 10Hz, 1Hz by default

Power Requirements:

- Power Supply Voltage: 2.8~4.3V

- Power consumption

- Acquisition 17mA

- Tracking 16mA

- Backup 8uA

Baud Rate: Adjustable 4800bps~115200bps Default: 9600bps

Communication Interface: UART

Sensitivity: -165dBm

Number of Channels: 22 (Tracking)/ 66 (Acquisition)

Time to First Fix:

- Cold Start: 32s

- Warm Start: 3s

- Hot Start: <1s

Antennas: Embedded patch antenna: 15.0mm × 15.0mm × 4.0mm

Accuracy:

- 2.5m GPS Horizontal Position Accuracy

Product Applications:

- Battery-operated mobile devices

- GPS tracker

- GPS navigator

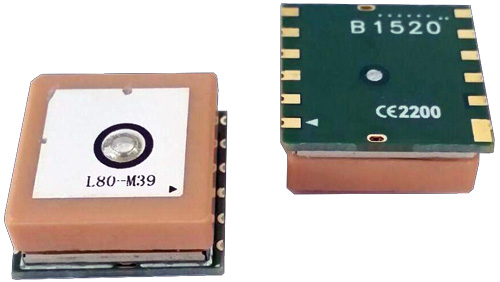

Quectel L80

L80 GPS module with an embedded patch antenna and LNA brings the high performance of MTK positioning engine to industrial applications. It is able to achieve the industry’s highest level of sensitivity, accuracy and TTFF with the lowest power consumption in a small-footprint leadless package. With 66 search channels and 22 simultaneous tracking channels, it acquires and tracks satellites in the shortest time even at the indoor signal level. The embedded flash memory provides the capacity for users to store some useful navigation data and allows for future updates.

Size: 16.0mm × 16.0mm × 6.45mm

Update Rate: Up to 10Hz, 1Hz by default

Power Requirements:

- Power Supply Voltage: 3.0V~4.3V Typical voltage: 3.3V

Baud Rate: Adjustable 4800bps~115200bps Default: 9600bps

Communication Interface: UART

Sensitivity: -165dBm

Number of Channels: 22 (Tracking)/ 66 (Acquisition)

Time to First Fix:

- Cold Start: 35s

- Warm Start: 30s

- Hot Start: 1s

Antennas: Embedded patch antenna: 15.0mm × 15.0mm × 4.0mm

Accuracy:

- 2.5m GPS Horizontal Position Accuracy

Product Applications:

- Battery-operated mobile devices

- GPS tracker

- GPS navigator

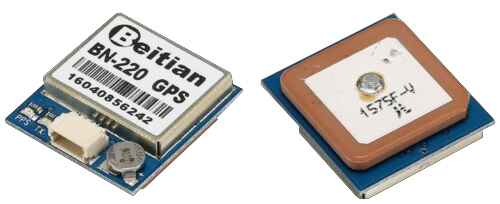

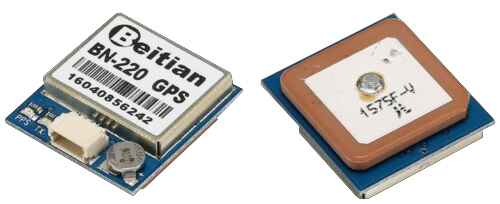

Beitian BN-220

BN-220 is a small gps receiver module, with 4M flash to save the configuration. It is mostly used with drones.

Size: 16.0mm × 16.0mm × 6.45mm

Update Rate: 1Hz-10Hz,Default1Hz

Power Requirements:

- Power Supply Voltage: 3.0V~5.5V Typical voltage: 5V

Baud Rate: Adjustable 4800bps~921600bps Default: 9600bps

Communication Interface: UART

Interface Protocol: NMEA-0183orUBX,DefaultNMEA-0183

Sensitivity: -167dBm

Number of Channels: 72Channel(Acquisition)

Time to First Fix:

- Cold Start: 26s

- Warm Start: 25s

- Hot Start: 1s

Antennas: Embedded patch antenna

Accuracy:

- 2m GPS Horizontal Position Accuracy

Product Applications:

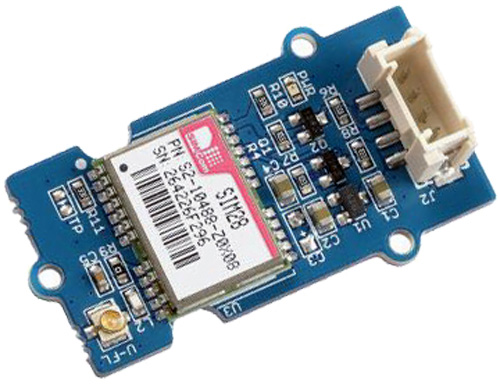

Grove – GPS Module

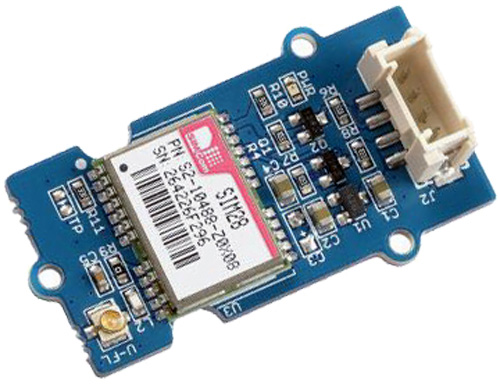

The Grove – GPS Module is the Seeed version of a GPS receiver that’s cost-efficient and field-programmable. It’s armed with a SIM28 and serial communication configuration.

Size: 40mm x 20mm x 13mm

Update Rate: 1 Hz, max 10 Hz

Power Requirements: 3.3/5V

Baud Rate: 9600 – 115,200

Communication Interface: UART

Sensitivity: -160dBm

Number of Channels: 22 tracking/66 acquisition channels

Time to First Fix:

- Cold starts with EASY: 13s

- Warm Starts with EASY: 1-2s

- Hot Starts: <1s

*EASY is a self-generate orbit protection

Antennas: Antenna included in the package

Accuracy: 2.5m GPS Horizontal Position Accuracy

Product Applications:

- GPS tracker

- GPS navigation

- Distance measurement

Other Product Features:

- Low power consumption

- Baud rates configurable

- Grove compatible interface

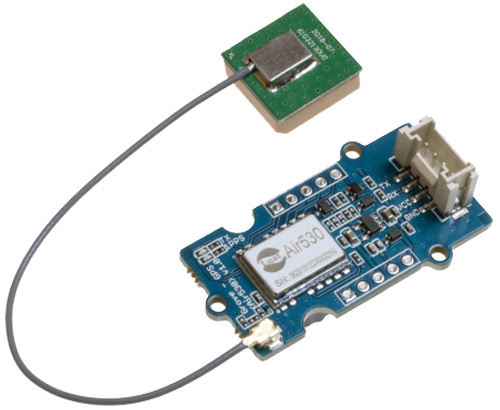

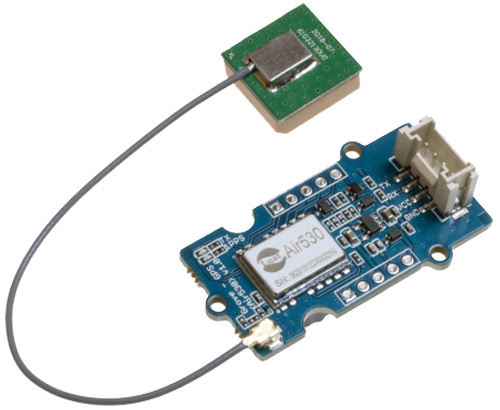

Grove – GPS (Air530)

Next up, we have the Grove – GPS (Air530). It’s a high-performance, highly integrated multi-mode satellite positioning and navigation module. It supports GPS / Beidou / Glonass / Galileo / QZSS / SBAS, which makes it suitable for GNSS positioning applications such as car navigation, smart wear, and drone.

If your GPS isn’t working well in urban areas or outdoors under only one or a few satellite modules, you should definitely check out this GPS module. Meanwhile, this module is capable of receiving more than 6 satellites at the same time and is able to work excellently even if there’s a very bad signal.

This GPS adopts the integrated design of RF baseband, which integrates DC/DC, LDO, LNA, RF front-end, baseband processing, 32-bit RISC based chip, RAM, FLASH storage, RTC and power management functions.

Size: 40mm x 20mm x 13mm

Update Rate:

Power Requirements: 3.3/5V

Baud Rate: – 9600 –921600

Communication Interface: UART

Sensitivity: – –166dBm

Number of Channels:

Time to First Fix:

- Cold start: 30 seconds

- Warm Start: 4 seconds

Antennas: Antenna included in the package

Accuracy: 2.5m Horizontal positioning accuracy

Product Applications:

- GPS tracker

- GPS navigation

- Distance measurement

Other Product Features:

- Highly integrated Multi-mode satellite positioning and navigation

- Grove compatible interface

Things to Consider before Purchasing a GSM Module

- Size: Similar to the GPS module the size matters in the case of a GSM module too. The smaller the size more compact our project will be.

- Communication Interface: It’s the interface used to communicate with the GSM Module. Serial/TTL or the USB interface is the most commonly used interface type by the GSM module.

- Communication Protocol: Communication protocol is used to communicate with the module. Most modules use AT Commands for this purpose. With AT commands, there will be commands to control each function of the module. We will use these commands to configure the module, to get information from the module, for services SMS, MMS and for voice and data links too.

- Communication Speed /Baud rate Refers to the speed of communication between the microcontroller and the GSM module, in the case of serial interface it is called the baud rate. Higher the baud rate allows for faster GSM data to be sent to the MCU.

- Communication Standard refers to the mobile standards like GSM, CDMA, WCDMA, LTE etc. GSM commonly stands for 2G, WCDMA for 3G and LTE for 4G communications. And the CDMA is no longer used in most areas of the world.

- Supported Frequency Bands refers to the frequency bands supported by the module. 900MHz and 1800Mhz are the most common 2G bands in India while 900MHz and 2100MHz are the 3G bands. And for 4G the most common bands used in India are B1 (2100 MHz), B3 (1800 MHz), B5 (850 MHz), B8 (900 MHz), B40 (TDD 2300 MHz), B41 (TDD 2500 MHz). So it is very important to choose the correct module which supports the bands supported by the carrier in the intended area.

- Supported services refers to the services supported by the module including voice, SMS and data. Some even support FM. Not all modules support all the protocols. So be careful when choosing the correct one.

- Data Transmission Throughout It refers to the maximum upload and download data speed supported by the module. For example, the most famous SIM800L has a maximum upload and download speed of 85.6kbps, while the SIM7500 module supports up to 150Mbps of download and 150Mbps of upload speed in LTE Category 4. So, if our applications need more bandwidth we must choose accordingly.

- Transmit Power: Transmission power of the module. Higher the power higher the reception, but with higher power usage. Not only that the power regulation may vary with countries so make sure to choose the correct module with proper transmission power rating as per your regulatory authorities.

- Power Requirements: This includes the working voltage and the power consumption. It is necessary to select the proper device because in most cases we will the modules will be battery powered and we will need to conserve the battery to the maximum.

- Price: Last but not least the price of the module is very important. It is very important to keep everything under the budget.

So now as we know what we are looking for in a GSM Module, let us take a look at a few GSM Modules in the market now:

SIMCOM SIM800L

SIM800L is a quad-band GSM/GPRS module, that works on frequencies GSM850MHz, EGSM900MHz, DCS1800MHz and PCS1900MHz. SIM800L features GPRS multi-slot class 12/ class 10 (optional) and supports the GPRS coding schemes CS-1, CS-2, CS-3 and CS-4. With a tiny configuration of 15.8*17.8*2.4mm, SIM800L can meet almost all the space requirements in user applications, such as smartphones, PDA and other mobile devices. SIM800L has 88pin pads of LGA package and provides all hardware interfaces between the module and customers’ boards.

It is also available as a module. The image of the module is given above.

Size: 15.8*17.8*2.4mm

Communication Interface: UART/USB

Communication Protocol: AT Command

Communication Speed /Baud rate: 1200bps to 115200bps

Communication Standard: GSM GPRS(2G)

Supported Frequency Bands: Quad-band: GSM 850, EGSM 900, DCS 1800, PCS 1900

Supported services: Voice, SMS, DATA GPRS

Data Transmission Throughout: GPRS data downlink transfer: max. 85.6 kbps/GPRS data uplink transfer: max. 85.6 kbps

Transmit Power: Class 4 (2W) at GSM 850 and EGSM 900, Class 1 (1W) at DCS 1800 and PCS 1900

Power Supply: 3.4V ~4.4V typical power consumption in sleep mode is 0.7mA

Ai Thinker A9 GPRS Series Module

Ai Thinker A9 GPRS Series Module can be used in a wide range of IoT applications and is ideal for IoT applications for home automation, industrial wireless control, wearable electronics, wireless location sensing devices, wireless location system signals, and other IoT applications. The A9 is a complete quad-band GSM / GPRS module in a compact design SMD package. Its stable performance, appearance of compact, and cost-effective, could meet the diverse needs of customers.

Size: 19.2*18.8*2.7mm

Communication Interface: UART/USB/I2C

Communication Protocol: AT Command

Communication Speed /Baud rate: 1200bps to 115200bps

Communication Standard: GSM GPRS(2G)

Supported Frequency Bands: 850, 900, 1800, 1900MHZ

Supported services: Voice, SMS, DATA GPRS

Data Transmission Throughout: GPRS data downlink transfer: max. 85.6 kbps/GPRS data uplink transfer: max. 42.8Kbps

Transmit Power: Class 4 (2W) at GSM 850 and EGSM 900, Class 1 (1W) at DCS 1800 and PCS 1900

Power Supply: 3.8V-4.2V, 4V power supply is recommended

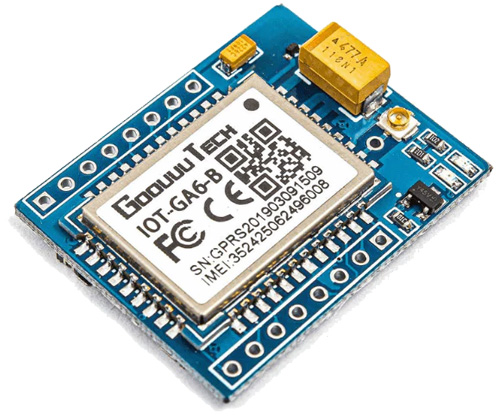

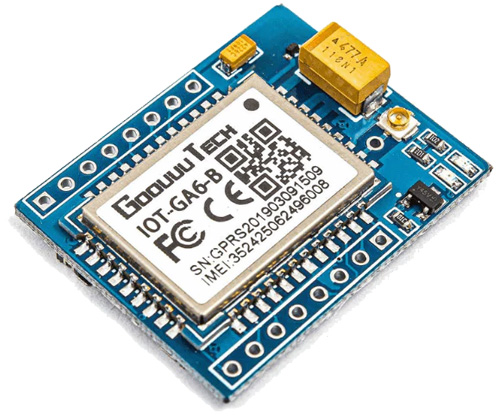

IoT-GA6 Mini GPRS GSM Module

GA6 module is a mini version of serial GSM / GPRS core development board based on GPRS A6 chip. This chip supports GSM/GPRS network, available for GPRS and SMS message data remote transmission. With the help of the A6 chip, GPRS never deactivated until its application is on and online. It supports either digital and analog audio, with HR, FR, EFR, AMR voice coding. This module can add voice, text, SMS, and data capabilities to your Arduino project. It has more price to performance value than the SIM800, SIM900 modules. This small and low power consumption module can communicate with the microcontrollers and Arduino boards through the UART interface, with the capability of command reception, including GSM 07.07, GSM 07.05 standards. It can be used for IoT projects, M2M applications, industrial automation, BMS projects, home automation, public transportation, personal tracking, electricity environment detection, wireless POS, smart metering, and other M2M applications

Size: 17.6*15.7*2.3mm

Communication Interface: UART/USB

Communication Protocol: AT Command

Communication Speed /Baud rate: 115200bps

Communication Standard: GSM GPRS(2G)

Supported Frequency Bands: Quad-band: GSM 850, EGSM 900, DCS 1800, PCS 1900

Supported services: Voice, SMS, DATA GPRS

Data Transmission Throughout: GPRS data downlink transfer: max. 85.6 kbps/GPRS data uplink transfer: max. 42.8kbps

Transmit Power: Class 4 (2W) at GSM 850 and EGSM 900, Class 1 (1W) at DCS 1800 and PCS 1900

Power Supply: 3.5V ~ 4.2V 3.3V Logic

Quectel M66

The M66 is a quad-band GSM/GPRS 2G module measuring 17.7mm × 15.8mm × 2.3mm which uses LCC castellation packaging. Based on the latest 2G chipset, it is optimized for data, SMS and audio transmission, and is designed for low-power IoT use cases that operate in harsh conditions. The M66 uses surface-mounted technology, making it ideal for large-scale manufacturing, which can have strict requirements on cost and efficiency. The M66’s ultra-compact profile makes it particularly suited to size-sensitive applications, and the module can serve a range of applications such as wearable devices, automotive, PDAs, asset tracking, POS, smart metering and telematics.

Size: 17.7mm × 15.8mm × 2.3mm

Communication Interface: UART/USB

Communication Protocol: AT Command

Communication Speed /Baud rate: 115200bps

Communication Standard: GSM GPRS(2G), Bluetooth 3.0

Supported Frequency Bands: Quad-band: GSM 850, EGSM 900, DCS 1800, PCS 1900

Supported services: Voice, SMS, DATA GPRS

Data Transmission Throughout: GPRS data downlink transfer: max. 85.6kbps/GPRS data uplink transfer: max. 85.6kbps

Transmit Power: Class 4 (2W) at GSM 850 and EGSM 900, Class 1 (1W) at DCS 1800 and PCS 1900

Power Supply: 3.3V ~ 4.6V

SIMCOM SIM868

SIM868 module is the complete Quad-Band GSM/GPRS module which combines GNSS( GPS/GLONASS/BDS) technology for satellite navigation. It has strong extension capability with abundant interfaces including UART, USB2.0, GPIO etc. The module provides much flexibility and ease of integration for customers’ applications.

Size: 17.6*15.7*2.3mm

Communication Interface: UART/USB

Communication Protocol: AT Command

Communication Speed /Baud rate: 1200bps to 115200bps

Communication Standard: GSM GPRS(2G)

Supported Frequency Bands: Quad-band: GSM 850, EGSM 900, DCS 1800, PCS 1900

Supported services: Voice, SMS, DATA GPRS

Data Transmission Throughout: GPRS data downlink transfer: max. 85.6 kbps/GPRS data uplink transfer: max. 85.6 kbps

Transmit Power: Class 4 (2W) at GSM 850 and EGSM 900, Class 1 (1W) at DCS 1800 and PCS 1900

Power Supply: 3.4V ~ 4.4V

Update Rate: Up to 10Hz, 1Hz by default

Power Requirements:

- Power Supply Voltage: 3.0V~4.3V Typical voltage: 3.3VCommunication Interface: UART

Sensitivity: -167dBm

Number of Channels: 33 tracking /99 acquisition

Time to First Fix:

- Cold Start: 28s

- Warm Start: 22s

- Hot Start: 1s

Antennas: External

Accuracy:

- 2.5m GPS Horizontal Position Accuracy

Conclusion

We are concluding this article hoping you got a better idea about the available option for a GPS/GSM module. In the article, we haven’t included any 3G/4G modules since they are not good for such an application, and they are very costly at this point. 2G GSM modules will give the best result because of their coverage and they are dirt cheap nowadays. And modules we have covered are the most common available once in the market and many other variants are there too. You may extend your scope to them if you can’t find a suitable one from the above suggestions.